| Unit Price: | USD 3500.0000 - 150000.0000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Basic Info

Model No.: DHB-FT

Processing Material: Natural Ingredients

Process: Ferment

Material: Stainless Steel 304 Or 316L

Size: 3HL To 100HL

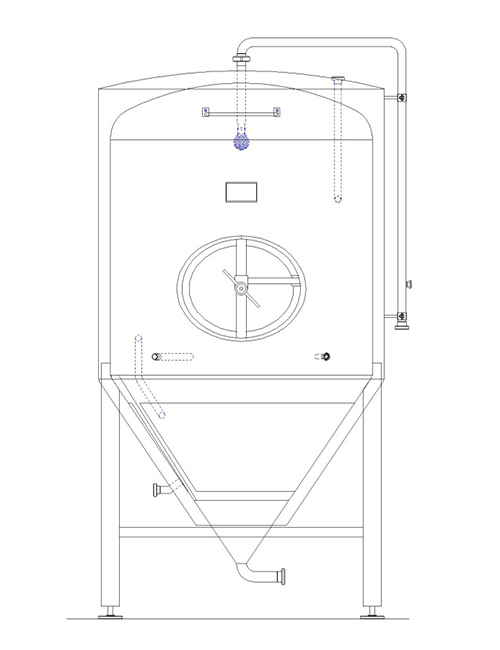

Appearance: Conical Fermenter With Bottom Opening Angle 60 Degree

Function: Beer Fermenting And Maturing

Construction: Two Sheet Walls With Cooling Jacket And Insulation

Cooling System: Jacket Cooling, With Glycol Inlet And Outlet

Manway Type: Side Manway Or Top Manway

Pressure: Tested 0.99 Bar, With Security Valve

CIP System: Equipped CIP Pipe And Spray Heads On Top

Drainage: Bottom Of The Tanks, Connector Size As To Capacity

Additional Info

Packaging: Standard export packing

Productivity: 100 set / month

Brand: Deao

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 20 set per month

Certificate: CE

HS Code: 8438400000

Port: Shenzhen Port,Dongguan Port,Hong Kong Port

Product Description

Brewpub 5HL Stainless Steel Beer Fermenter

Beer brewing tanks size are normally following the capacity of brewhouses, in size up to 100HL. Cylindrical - conical beer tanks or horizontal beer tanks are available. All tanks are made of stainless steel, for brewpub, we can make decorative tanks copper clad. Tanks are constructed with top head cover, wall, cone and jacket. 4 or 3 legs with pressure plates. Cone is usually with opening angle 60 degree.

Details of the our product are featured within content below:

for example 6000L fermentation tank

equipped with:

Fermentation Tanks Control system:

1. Tanks Temperature automatic controlled by combined PLC system

2. Tanks controlled by individual temperature controller without cold water tank.

CIP for Fermentation tanks

1. Mobile CIP

two tanks 150L, acid tank and alkaline tank with heating elements

with pump

2. Automatic CIP system

For scale brewery, we will design automatic cleanning system as to your detailed need.

All the valves are pneumatic valves, which are controlled by computer.

With a series of recycle and cleaning liquid storage tanks as to number of fermentation tanks

Pumps

Cooling plant – Glycol for wort and vessel cooling

in compact design:

for internal installation

made as one-circle system

refrigerant: R134a

glycol wage: 20%

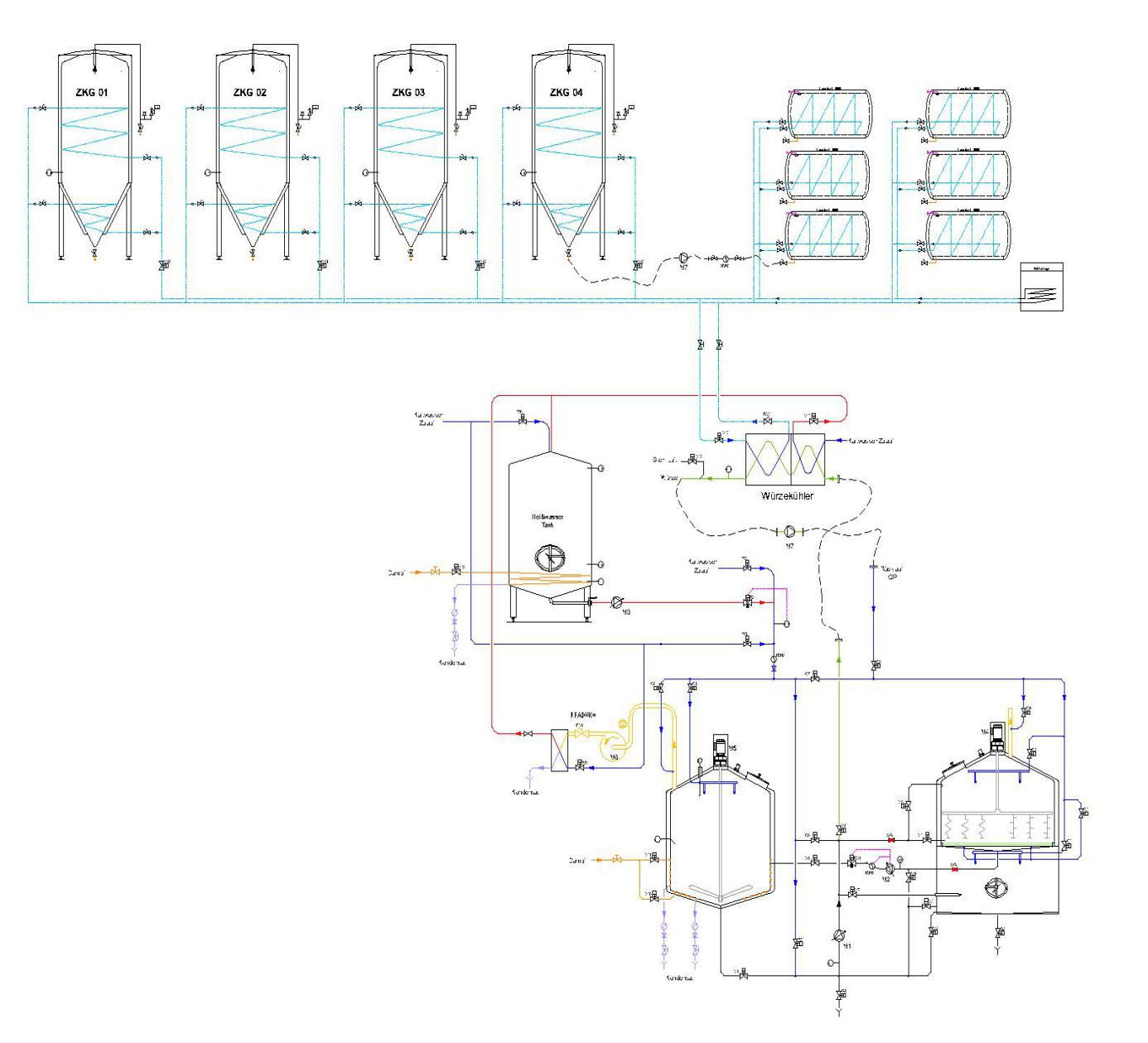

Complete flowchart for example:

CONTACT US

Dongguan Deao Food Equipment Co.,Ltd

Contact Person: Darwain Wang

Phone:86-0769-82868162

Fax:86-0769-82868162

Address: Shanglin industry park, Hengli town, Dongguan,Dongguan,Guangdong