| Payment Type: | L/C,T/T,D/P |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: DHB-3000-4a

Processing Material: Natural Ingredients

Process: Ferment

Additional Info

Packaging: Standard export packing

Productivity: 10 set / month

Brand: Deao

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 20 set per month

Port: Shenzhen Port,Dongguan Port,Hong Kong Port

Product Description

Dongguan Deao has been manufacturing various brewery equipment and exporting them to overseas markets and setting up Pub chain stores in China. I work with a number of western colleagues from the Germany, Australia, and Russia.

We manufacture both American type and European type brewing equipment, from homebrew, 3hl, 5hl to 10hl, 20hl to 30hl, 50hl commercial brewery, and we also undertake handcrafted beer brewery construction for you on an Original Equipment Manufacturer (O.E.M).

Details of the our product ranges are featured within content below:

| Brew Capacity | 10HL | 15HL | 20HL | 30HL | 50HL |

| Operation | Manual / Partly automatic control |

Manual / Partly automatic control |

Partly automatic control / fully automatic control |

Partly automatic control / fully automatic control |

Fully automatic control |

| Brew cycle | 1-3 brew / day |

1-3 brew / day |

3-5 brew / day | 3-6 brew / day | 5-8 brew / day |

| Each Fermenter cacapacity | 10HL, 20HL or 30HL | 15HL, 30HL or 45HL | 20HL to 100HL | 30HL to 180HL | 50HL to 400HL |

| Heating | Steam Heating | Steam Heating | Steam Heating | Steam / Direct Fire Heating |

Steam / Direct Fire Heating |

This brewhouse is planned with a capacity of 10 hl to 50 hl per brew cycle.

The whole brewhouse is built from stainless steel.

It consists of 4 vessels or 5 vessels:

· Mash tun

· Lauter vessel

· Wort kettleand

· Whirlpool

· Additional tun added as to requirement.

·In the back part of the unit the control panel is mounted with the control and feedback devices.

· Manual Operation:

All valves are operated directly on the valves. In this case the piping is built, that the operation is comfortable for the operator.

All motors will be started by switches on the control panel.

The temperature control is done by a simple temperature controler without timing control.

Optional for additional charge:

Electrical Heating System of the Copper

Partly automated control

Fully automated control

Touch panel

Visualization software for the brew process

Input for recipes and fault analytics

With electrical sensors and signalization device

Automated, with pneumatic valves in the piping

Flow meter to control the lautering speed

In the fully automated control, every option is included

Vapour condensor consists of: heat exchanger, valves and fan to remove boiling vapors

Part II. cylindrical-conical fermentation and storage tanks with a capacity of 10hl to 150hl

Part III. Hot water tank 20hl to 150hl

with circulation pump made of stainless steel

with automatic temperature regulation

with dry operation protection of pump

made of stainless steel double walled, completely insulated

with steam heated

with all connections and fittings

Part IV. Malt Mill and Conveyor

Part V. Steam generator

Steam capacity: as to brewhouse capacity

Heating: electricity, oil or gas

equipped with:

with gas pressure regulating valve

with adjusting container made of stainless steel

with fine filter

with water meter

with all security fittings

with complete internal piping

with electronic control

Part VI. Cooling plant – Glycol for wort and vessel cooling

in compact design:

for internal installation

made as one-circle system

refrigerant: R134a

glycol wage: 20%

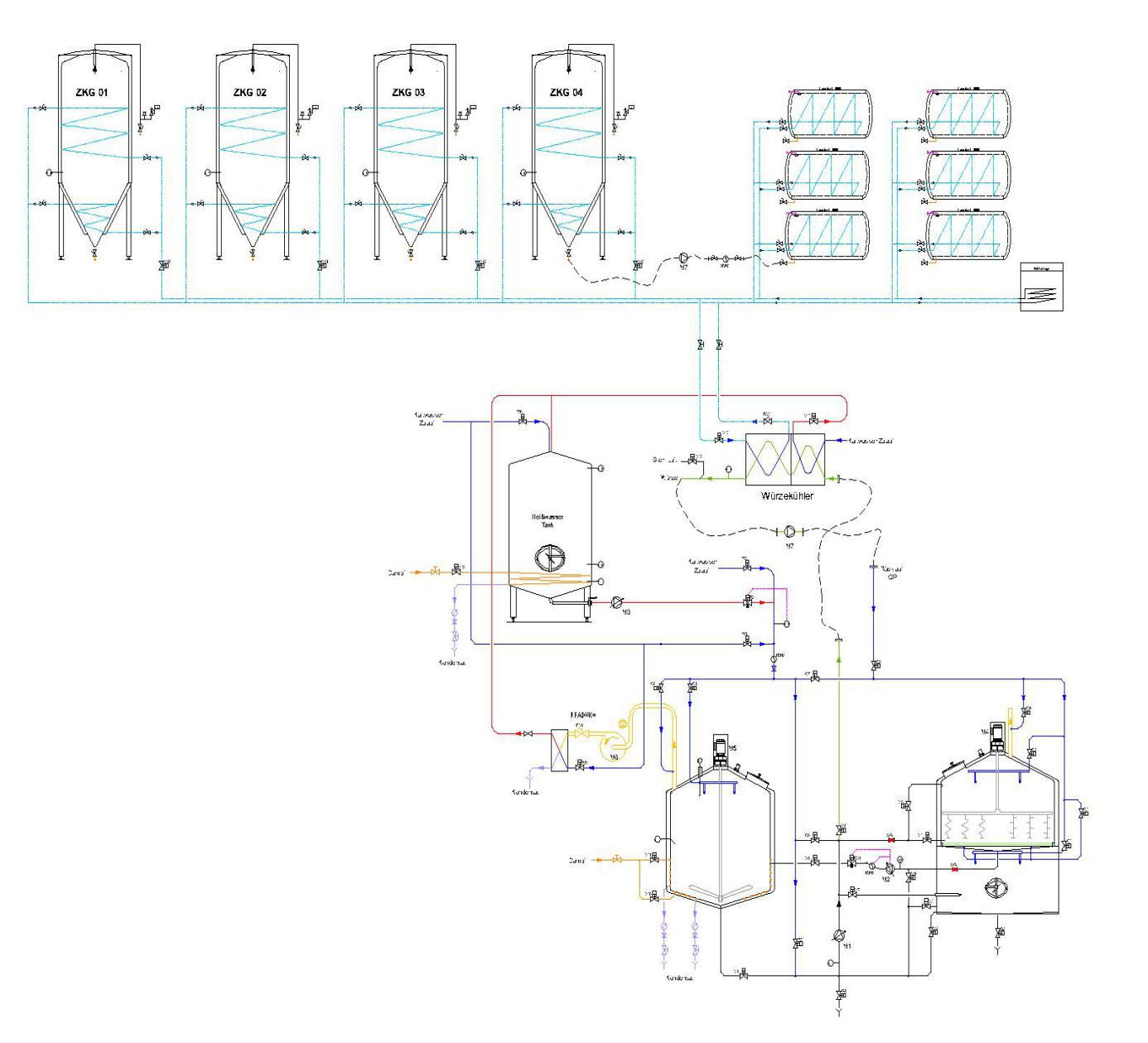

Complete flowchart for example:

CONTACT US

Dongguan Deao Food Equipment Co.,Ltd

Contact Person: Darwain Wang

Phone:86-0769-82868162

Fax:86-0769-82868162

Address: Shanglin industry park, Hengli town, Dongguan,Dongguan,Guangdong