| Unit Price: | USD 250000.0000 - 470000.0000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: DHB-3000

Processing Material: Natural Ingredients

Process: Ferment

Material: SUS304 OR 316L

Size: Bespoke Design

Electrical Parts Brand: Siemens, SMC

Motors: SEW

Operation: Semi-Automatic, Manaual Operation, Fully

Power: 380 V, 3 Phase

Warranty: 3 Year

Capacity: Effective 3HL To 50HL

Type: 3, 4 Vessels

Additional Info

Packaging: case and fix in container

Productivity: 100 set

Brand: deao

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10 set per month

Certificate: CE

HS Code: 8343400000

Port: Dongguan,Shenzhen,Hongkong

Product Description

Commerical Craft Beer Factory with Capcity 30HL

For the size of 30HL Beer Factory, 2 vessel brewhouse is most cost effective choice, 3 vessels is most welcome by customers and 4 vessel kit can greatly faster the brew turns and cycle.

Version 1

Version 2

Version 2

The details of this brewhouse is featured as following photos and descriptions:

Control Cabinet and Siemens Electrical Parts

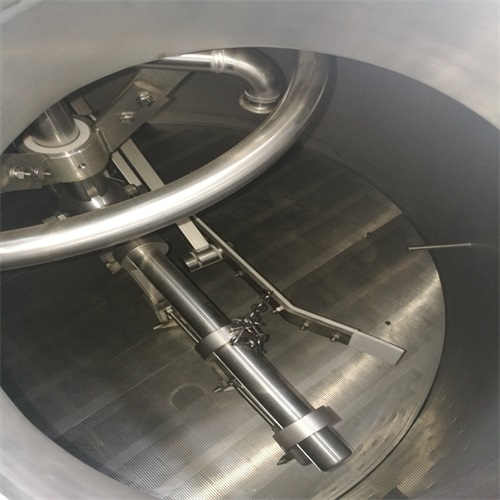

Raker and SEW motor

Welding and polishing

Glass manhole

Internal Cooker and agitator

Underback with level sensors

Lauter tun manhole

Danfoss brew water mixer

Quality Flowmeter

Pneumatic valves

Boiling vapor heat collection

Cellar Tanks

1. Conical fermentation tank and horizontal lagering tank are available.

2. SUS304, internal wall 4mm, inner welds polished; outer shell 3mm, surface polished.

3. With cooling jacket on cylinder and conical bottom. Equipped with chiller and glycol tank.

4. Side manhole, top CIP spray heads, security valve and pressure measurement.

5. Conical fermenter is 60 degree bottom, equipped with tap, temperature sensor, faucet.

6. Glycol inlet and outlet.

7. PU insulation 50mm.

Brew Water Plant

Cooling plant – Glycol for wort and vessel cooling

Keg filling machine ( Automatic canning line or bottling line optional)

KEG Filling and cleaning machine Multimat MT2

Additional bottle cleaning station (6 position)

Addtional bottle filler AF80

Steam Generator

Electric heating steam generator

380V, 150KG / H

with security valves and anti-dry heating protection

Malt Mill, Malt Conveyor, Malt Transport Pump, Wet Malt Mixer, Heat Exchanger, Hops Gun, Yeast Cultural Tank, Air compressor, Chiller and all other accompanying equipment are available from our company. Please write down your equipment list, we make a configuration and complete turnkey solution for you.

CONTACT US

Dongguan Deao Food Equipment Co.,Ltd

Contact Person: Darwain Wang

Phone:86-0769-82868162

Fax:86-0769-82868162

Address: Shanglin industry park, Hengli town, Dongguan,Dongguan,Guangdong