| Payment Type: | L/C,T/T,D/P |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Additional Info

Packaging: Wooden case for LCL; Plastic film wrapped fixing for FCL

Productivity: 100 Set

Brand: Deao

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 10 Set per month

Certificate: CE

HS Code: 8438400000

Port: Shenzhen Port,Hongkong Port,Dongguan Port

Product Description

10hL Craft Beer Brewing Micro Brewery Equipment

The craft beer microbrewery equipment we offer are made of 304 stainless steel or 316l with stated parameters, and also can be custom made to your specifications of beverage brewing equipment. Find everything you need to fit your craft beer brewing supply.

3 vessel automatic brewhouse ( German style )

example, 3 vessel brewhosue DHB 1000-3

Details as following descriptions:

1. Automatic Operation:

All valves are operated directly on the touch panel, good quality pneumatic valves.

All motors will be started by switches on the control panel, SEW motor used.

The system can save recipes and run brewing automatically.

PLC controlled fermentation tanks and storage tanks.

Siemens Control system and touch panel

Agitator and SEW motor

Internal Wort Cooker

Glasssight manhole

Underback with level sensors

Lauter tun manhole security sensor

Pneumatic valves and pipwworks

Danfoss brew water mixer

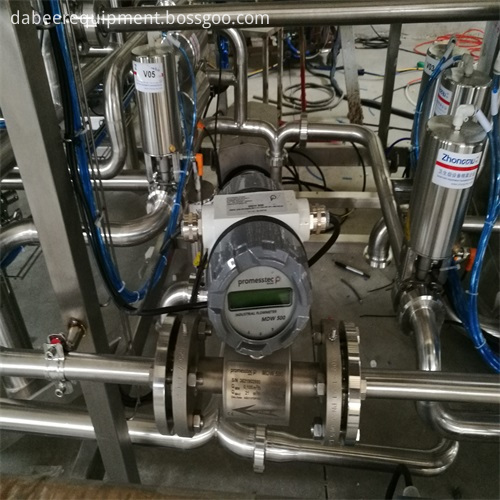

Flow meter

10 hl fermentation tank and conditioning tanks 10 pcs

1. Conical fermentation tank and horizontal lagering tank are available.

2. SUS304, internal wall 3mm, inner welds polished; outer shell 2mm, surface polished.

3. With cooling jacket on cylinder and conical bottom. Equipped with chiller and glycol tank.

4. Manhole on the top, top CIP spray heads, security valve and pressure measurement.

5. Conical fermenter is 60 degree bottom, drain at the center of bottom, equipped with sample tap, temperature sensor, beer faucet.

6. Cold water inlet and outlet.

7. PU insulation 50mm.

Hot water tank 20hl

Cooling plant – Glycol for wort and vessel cooling

Keg filling machine

KEG Filling and cleaning machine Multimat MT2

Additional bottle cleaning station (6 position)

Addtional bottle filler AF80

Malt Mill, Malt Conveyor, Malt Transport Pump, Wet Malt Mixer, Heat Exchanger, Hops Gun, Yeast Cultural Tank, Air compressor, Steam Generator, Chiller and all other accompanying equipment are available from our company. Please write down your equipment list, we make a configuration and complete turnkey solution for you.

CONTACT US

Dongguan Deao Food Equipment Co.,Ltd

Contact Person: Darwain Wang

Phone:86-0769-82868162

Fax:86-0769-82868162

Address: Shanglin industry park, Hengli town, Dongguan,Dongguan,Guangdong